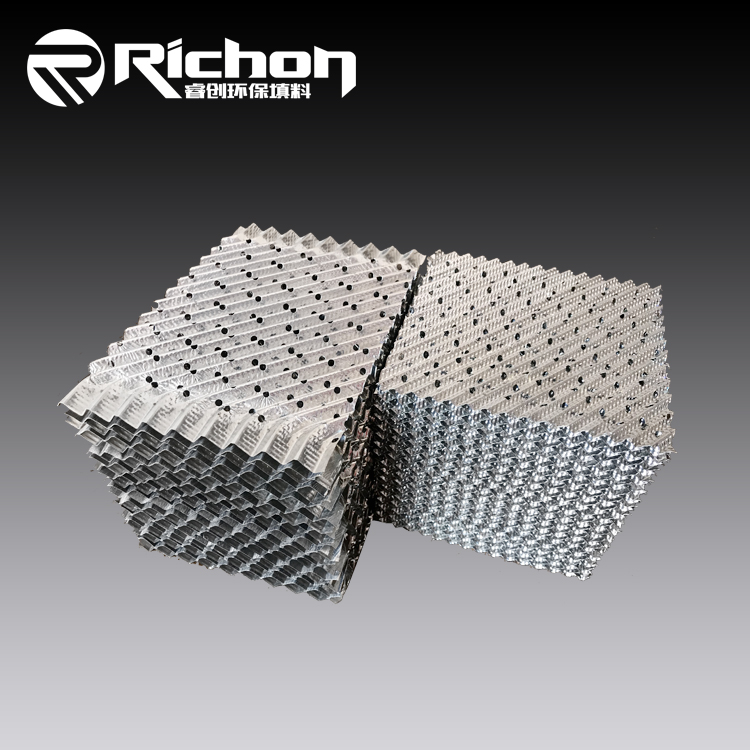

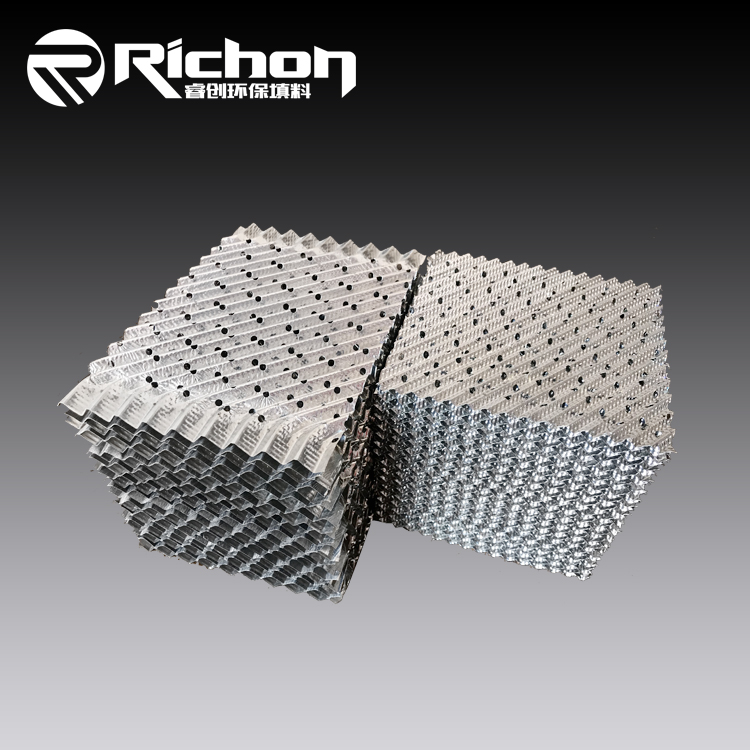

Metal Perforated Plate Structured Packing For Air Separation Column

Metal Corrugated Plate Packing is made from perforated plate with channel corrugation on surface, and remains structure feature of metal wire gauze packings. It consist a series of metal sheets specially arranged and engineered to encourage contact between liquid in a chemical process tower. First introduced in the 1970s, corrugated structured packing remains in use today as an afforsable, efficient and reliable alternative to over other tower packings.

Corrufated packing is available in two main configurations: X and Y. In Y packings, the more common of the two, sheet align at a 45-degreee angle from horizontal. X packings, on the other hand, feature a 60-degree inclination, provide a lower pressure drop that makes then better suited for high-capacity applications.

It strengthens uniform liquid distribution and surface wetting ability, which increases mass transfer efficiency. The unit height is 50-200 mm per coil, and the packing is prepared in blocks when diameter is larger than 1.5 m.

It is formed from vertical sheets of corrugated metal with the angle of the corrugation reversed in adjacent sheets to form an open structure with inclined flow channel. Its structure can not only change the distribution of liquid, but also increase the transfer efficiency.

|

Packing type

|

Theoretical plate number m-1 |

Specific surface area m2/m3 |

Void volume m3 |

Pressure drop MPa/m |

Bulk density kg/m3 |

Maximal F factor m/s (kg/m3)0.5 |

Liquid loading m3/m2.hr |

| 125Y |

1-1.2 |

125 |

0.98 |

2 × 10-4 |

85-100 |

3 |

0.2-100 |

| 250Y |

2-2.5 |

250 |

0.97 |

3 × 10-4 |

170-200 |

2.6 |

0.2-100 |

| 350Y |

3.5-4 |

350 |

0.94 |

2 × 10-4 |

240-280 |

2.0 |

0.2-100 |

| 500Y |

4-4.5 |

500 |

0.92 |

3 × 10-4 |

170-200 |

1.8 |

0.2-100 |

| 125X |

0.8-0.9 |

125 |

0.98 |

1.4 × 10-4 |

85-100 |

3.5 |

0.2-100 |

| 250X |

1.6-2 |

250 |

0.97 |

1.8 × 10-4 |

170-200 |

2.8 |

0.2-100 |

| 350X |

2.3-2.8 |

350 |

0.94 |

1.3 × 10-4 |

240-280 |

2.2 |

0.2-100 |

| 500X |

2.8-3.2 |

500 |

0.92 |

1.8 × 10-4 |

170-200 |

2.0 |

0.2-100

|

• Material: Include carbon steel, stainless steel, inconel, brass, copper and nickel alloys

• Package: Pallet, wooden carton

Metal Corrugated Plate Structured Packing Feature

♦ Strong resistance to fouling

♦ Low resistance, even gas and liquid distribution

♦ High efficiency, large flow rate and unremarkable magnifying effects

♦ It's applied to negative pressure, normal pressure and pressurization operation

Metal Corrugated Plate Structured Packing Application

» Widely used in unit operations like rectification, absorption and extraction.

» Suitable for chemical industry, chemical fertilizer industry, oil refining, petrochemical industry and natural gas industry.

» Vacuum and atmospheric crude oil fractors

» Fcc main fractionators

» TEG contactors

Structured Packing

Structured Packing