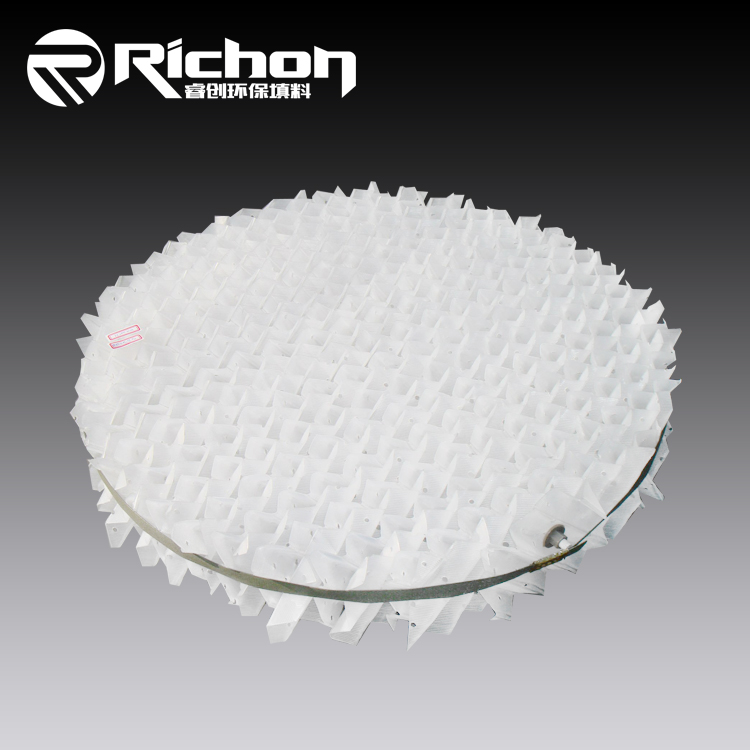

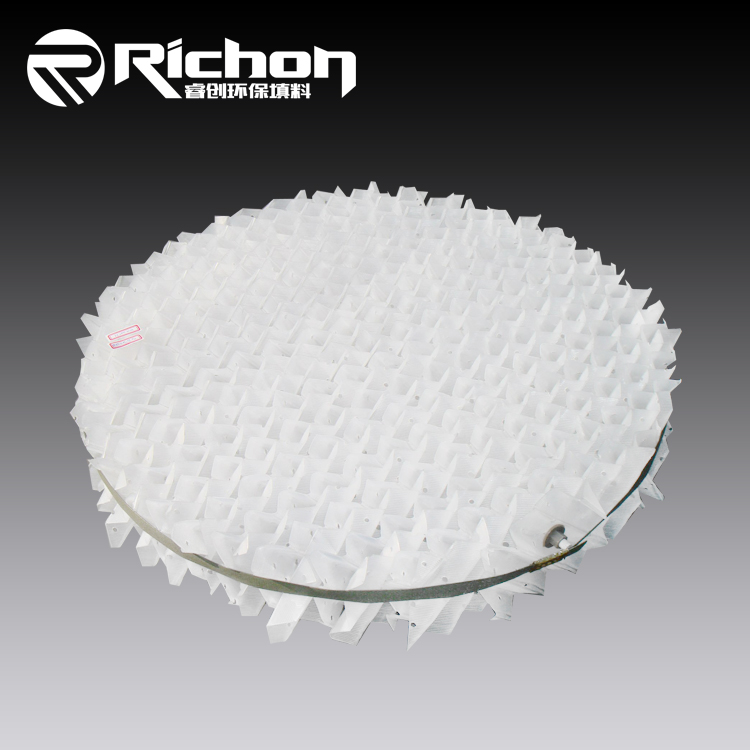

Plastic Structured Packing -Corrugated Plate Packing / Wire Guaze Packing

Plastic Structured Packing has similar structure with metal structured packing, which can be divided into plate packings and wire gauze packings. Plastic structured packing can

be made of PP, PA, PVDF, CPVC and other plastic materials, which has excellent high temperature resistance performance and corrosion resistance performance. It is an alternative

to ceramic structured packing.

Types

• Wire gauze packings: Wire gauze packings is commonly made of PP materials

• Plate packings: Plate packings can be perforated plate packings or no perforation packings. Perforated plate packings can supply better mass transfer efficiency and

smooth surface plate packings supply good stiffness.

The Technical Parameter Of Plastic Structured Packing

| Model |

Theoretical Plate Number

(piece/m) |

Specific Area

(m2/m3) |

Void Volume

(m3/m3) |

Bulk Density

(kg/m3) |

Liquid Loading

(m3/m2·h) |

| 125Y |

1–2 |

125 |

0.985 |

37.5 |

0.2–100 |

| 250Y |

2–2.5 |

250 |

0.97 |

75 |

0.2–100 |

| 350Y |

3.5–4 |

350 |

0.95 |

105 |

0.2–100 |

| 500Y |

4–4.5 |

500 |

0.93 |

150 |

0.2–100 |

| 125X |

0.8–1.9 |

125 |

0.985 |

37.5 |

0.2–100 |

| 250X |

1.5–2 |

250 |

0.97 |

75 |

0.2–100 |

| 350X |

2.3–2.8 |

350 |

0.958 |

105 |

0.2–100 |

| 500X |

2.8–3.2 |

500 |

0.93 |

150 |

0.2–100 |

Plastic Structured Packing Features

» High efficiency, high capacity and low pressure drop as metal structured packing.

» Excellent corrosion resistance performance to be used in high corrosive applications.

» Better high temperature resistance than metal structured packing and ceramic structured packing. Working

» Temperature of PP packings can reach 100 °C and PVDF packings can reach 150 °C.

» Perforated plates packings with small holes on surface increase mass transfer efficiency.

» High sheet stiffness of no perforation packings in less separation requirements applications.

Plastic Structured Packing Applications

♦ Air separation plant direct contact cooler.

♦ Flue gas cooler.

♦ Seawater scrubber.

♦ HCl absorber.

♦ SO2 absorber.

♦ ClO/ClO2 scrubber.

♦ Deaerators.

Structured Packing

Structured Packing