Water Treatment Series

Water Treatment Series

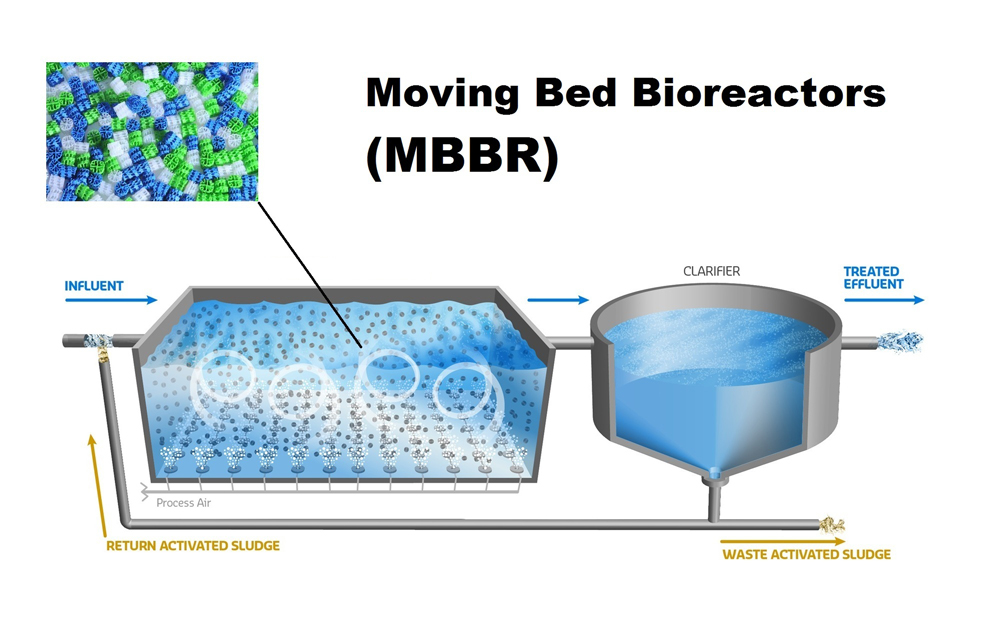

| MBBR is a moving media system, used in Integrated Fixed-lm Activated Sludge (IFAS) and moving bed biofilm reaction (MBBR) system. The wastewater goes through suspending media of MBBR reactor, forming biological membrane on the surface of media gradually. With the action of microbial on the biological membrane, wastewater is purified. MBBR biofilm carrier can move freely in the reactor with the mixing of the water. For the aerobic reactor, the aeration will make the media move; for the anaerobic reactor, mechanic mixing will make the media move. Our MBBR biofilm carrier is new-developed media, has better treatment effect compared with traditional media. We offer advanced wastewater treatment solutions for the industrial and municipal markets. These solutions significantly increase the capacity and efficiency of existing wastewater treatment plants, while minimizing the size of new plant deployments. |

.jpg)

| Model | R-PE01 | R-PE02 | R-PE03 | R-PE04 | R-PE05 | R-PE06 | R-PE07 | R-PE08 | R-PE09 | R-PE10 |

|

Spec (mm) |

12*9 | 11*7 | 10*7 | 16*10 | 25*12 | 25*12 | 35*18 | 5*10 | 15*15 | 25*4 |

| Hole Numbers (pcs) | 4 | 4 | 5 | 6 | 19 | 19 | 19 | 7 | 40 | 64 |

| Efficent Surface (m2/m3) | >800 | >900 | >1000 | >800 | >500 | >500 | >350 | >3500 | >900 | >1200 |

| Density (g/cm3) | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 0.96-0.98 | 1.02-1.05 | 0.96-0.98 | 1.02-1.05 | 0.96-0.98 | 0.96-0.98 |

| Packing numbers (pcs/m3) | >630000 | >830000 | >850000 | >260000 | >97000 | >97000 | >33000 | >2000000 | >230000 | >210000 |

| Porosity (%) | >85 | >85 | >85 | >85 | >90 | >90 | >92 | >80 | >85 | >85 |

| Dosing ratio (%) | 15-67 | 15-68 | 15-70 | 15-67 | 15-65 | 15-65 | 15-50 | 15-70 | 15-65 | 15-65 |

|

Membrane-forming time |

3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 | 3-15 |

| Nitrification efficiency (gBOD5/M3.d) |

400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 400-1200 | 300-800 | 500-1400 | 500-1400 | 500-1400 |

| BOD5 oxidation efficiency (g/BOD5/M3.d) |

2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 2000-10000 | 1000-5000 | 2500-15000 | 2500-15000 | 2500-15000 |

| COD oxidation efficiency (g/COD5/M3.d) |

2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 2000-15000 | 1000-10000 | 2500-20000 | 2500-20000 | 2500-25000 |

| Applicable temperature (℃) |

5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 | 5-60 |

| Life span (Year) | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 |

| 1. Excellent mechanical properties and excellent resistance to shock load performance. We selected 100% Virgin unfilled HDPE materials,which ensures its excellent mechanical properties and its service life up to 30 years. |

2. Rapid carrier bio film formation mechanism, and high quality bio film. We choose the best performance HDPE materials to do biocompatibility and invasive test,to improve its biofilm quantity and biofilm formation speed. |

|

3.Large specific surface area and strong impact resistance. HDPE Bofilter media made by secial processing technology with peculiar ring structure design,to make it large specific surface area and strong impact resistance. |

4. Super decarburization, ammonia nitrogen removal capacity,Deoxidation and phosphorus removal effect is good. |

|

| 5. Flexible way of engineering application, Simple operation and maintenance. |

| ♦ Thermofor biofilm reactor to remove organics and denitrify ♦ Active sludge process It combines biofilm and activated sludge process in the same treatment unit. it improve the ability to remove BOD/COD and strengthen the function of denitrification and dephosphorization. such process is suitable for the remounlding of activated sludge process, no need of rebuilding. |

|

Mobile:15932856852 / 18270725559

Email:carrie@richonpacking.com / lynne@richonpacking.com