Ceramic Random Packing

Ceramic Random Packing

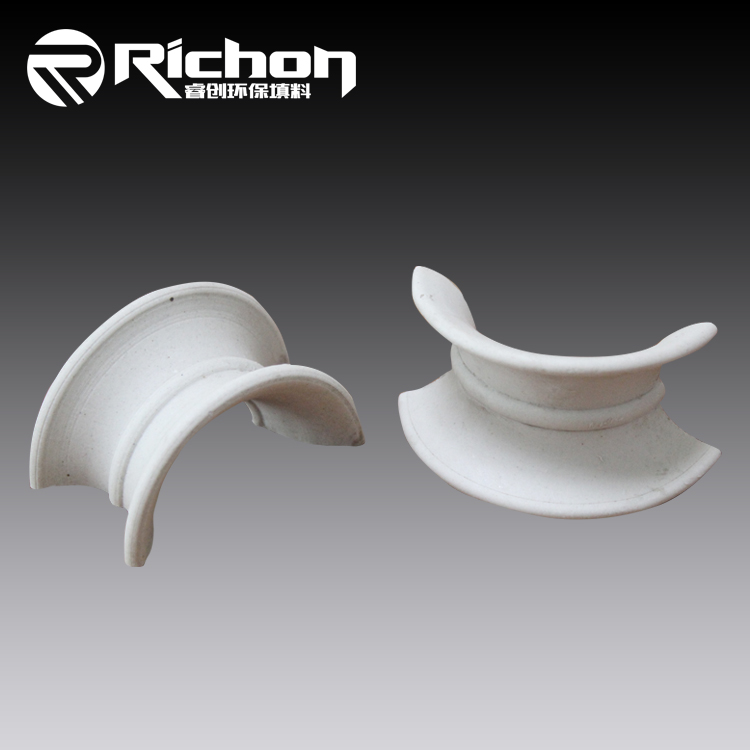

| Ceramic Intalox Saddle Ring is the advanced products of ceramic Berl saddle ring. It changes the arched surface and make the interior radius of curvature different. This design can overcome the nesting problem basically. Ceramic intalox saddle ring make the porosity be evenly distributed and the distribution of fluid be improved. It has higher capacity and lower pressure drop than ceramic raschig ring. It is most frequently used high-performance packing and exhibit advantages for most applications in comparison with other shapes. Their smooth surface imparts a high chemical resistance and provides Ceramic Intalox saddle rings (Ceramic Saddles ) with a high level of stability. Due to their simple form, ceramic saddles can be produced at a relatively low cost. |

| Al2O3 | 17-23% | Item | Value | |

| SiO2 | >70% | Water Absorption | <0.5% | |

| Fe2O3 | <1% | Apparent porosity | <1% | |

| CaO | <1.5% | Specific Gravity | 2.3-2.35 | |

| MgO | <0.5% | Operation Teperature | 1000°C | |

| K2O+Na2O | <3.5% | Moh's hardness | > 7scale | |

| Other | <1% | Acid resistance | >99.6% |

| Size | Surface Area | Void Rate | Packing Number | Pakcing Density | Dry packing Factor | |

| inch | mm | m2/m3 | % | piece/m3 | kg/m3 | m-1 |

| 1" | 25 | 250 | 74 | 53500 | 700 | 320 |

| 1 1/2" | 38 | 164 | 78 | 15000 | 600 | 170 |

| 2" | 50 | 124 | 77 | 6800 | 510 | 130 |

| 3" | 76 | 95 | 77 | 1950 | 500 | 127 |

Mobile:15932856852 / 18270725559

Email:carrie@richonpacking.com / lynne@richonpacking.com